Call or Text: +1 (208) 425-2990

Email: Sales@DroneSprayPro.com

Agricultural Drone Sprayer Maintenance: Tips for Long-Term Use

Share

Want to keep your agricultural drone sprayer running smoothly and lasting longer? Here’s what you need to know:

- Daily Cleaning: Clean tanks, nozzles, motors, and the frame to prevent chemical buildup and damage.

- Regular Maintenance: Inspect and maintain nozzles, pumps, batteries, motors, and propellers on a set schedule.

- Rust Prevention: Use protective sprays and lubricants to shield metal parts from corrosion.

- Off-Season Storage: Store batteries at 40–60% charge, flush spray systems, and protect the drone from pests and moisture.

- System Checks: Calibrate spray systems, test flow rates, and inspect components before critical applications.

Key Tip: A quick 10–30 minute pre-flight inspection can save you from costly repairs and downtime. Regular care ensures your drone performs at its best, even during peak spraying seasons.

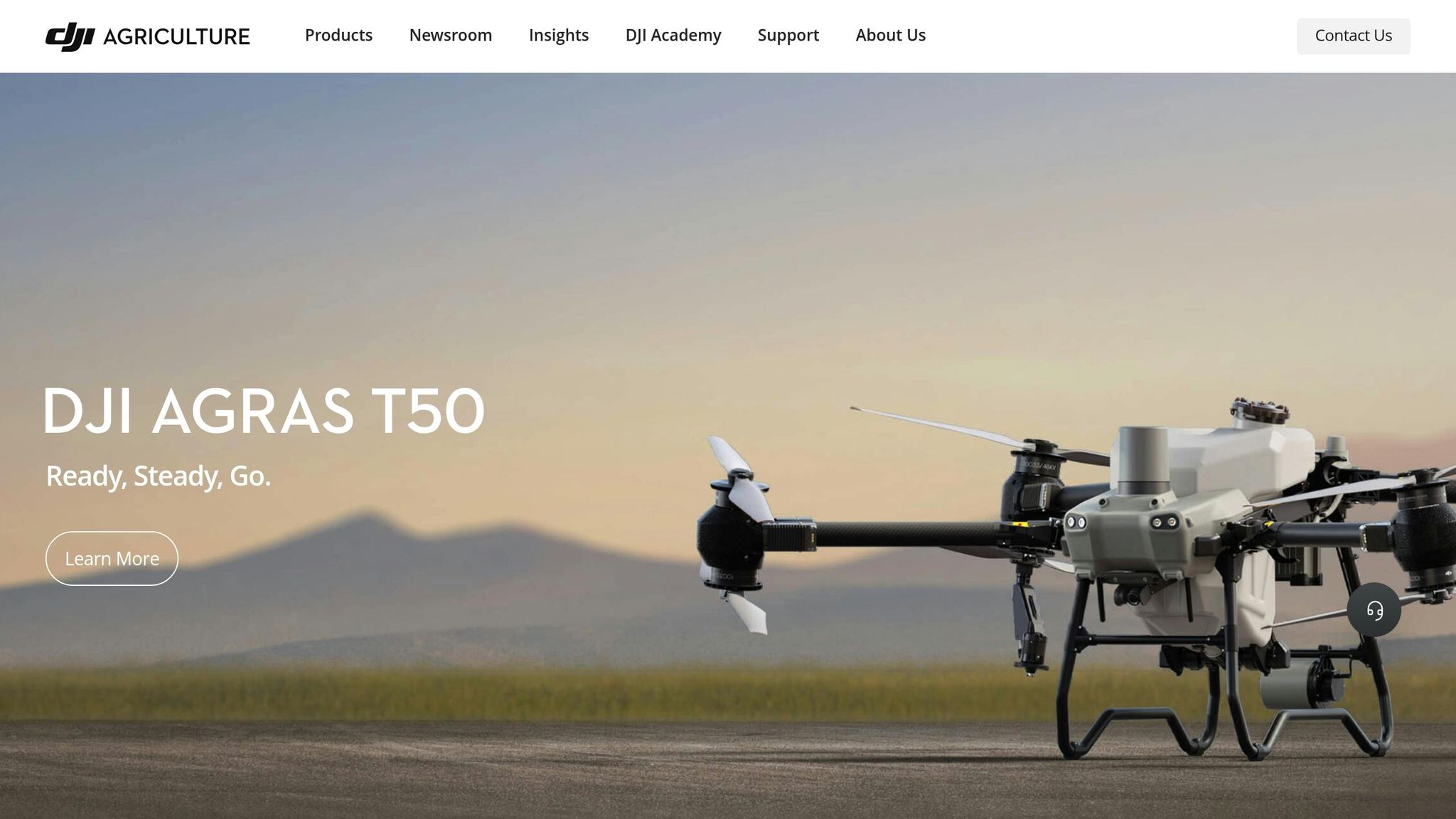

Essential Maintenance Guide for Your DJI Agras Drone

Daily Cleaning Steps

Keeping up with daily cleaning helps avoid chemical buildup and prevents expensive repairs down the line.

Tank and Nozzle Cleaning

Start by emptying any leftover spray solution from the tank. Then, fill the tank with clean water and briefly run the system to flush out any remaining chemicals. If there’s persistent buildup, try warm water mixed with a mild detergent.

For nozzle care:

- Unscrew the nozzles and soak them in warm, soapy water.

- Use a soft brush to gently remove any residue.

- Check each nozzle for blockages.

- Reattach the nozzles, ensuring they’re properly aligned.

Motor and Propeller Care

The motors and propellers are essential for safe and efficient operation, so they deserve extra attention. To keep them in top shape:

- Use a brush to clear debris from motor housings and inspect the propeller edges for any damage.

- Wipe the propellers clean with a microfiber cloth dampened with 70% isopropyl alcohol.

- Spin the motor bearings to ensure they rotate smoothly.

Frame Cleaning

The drone’s frame is susceptible to chemical corrosion, so handle it carefully. Follow these steps:

- Initial Cleaning: Use a microfiber cloth dampened with clean water to wipe down the entire frame. Pay special attention to joints and connection points where chemicals tend to gather.

- Deep Cleaning: For tougher residues, lightly dampen a microfiber cloth with 70% isopropyl alcohol and gently clean the affected areas. Avoid spraying solutions directly onto the frame to protect the electronics.

- Final Inspection: Look over the frame for any signs of wear, corrosion, or damage. Focus on key areas like connection points, landing gear, the battery compartment, and the control board housing.

Allow the drone to air dry in a well-ventilated area to finish your daily cleaning routine.

Regular Parts Maintenance

After completing daily cleaning, these regular maintenance steps help ensure your equipment stays in top working condition over time.

Nozzle and Pump Care

Regular inspection and timely replacement of worn parts are key. Check nozzles during each session for signs of wear or blockages. Follow the cleaning instructions mentioned earlier - avoid using metal tools that could damage the nozzles. This routine complements the daily cleaning process.

| Component | Inspection Frequency | Signs of Wear | Action Required |

|---|---|---|---|

| Nozzles | Daily | Uneven spray pattern, dripping | Clean or replace |

| Pump | Weekly | Reduced pressure, leaks | Inspect seals and tighten fittings |

| Hoses | Monthly | Cracks, bulging | Replace if compromised |

To maintain consistent performance, calibrate the spray system before each use. Typically, nozzles and pump diaphragms should be replaced after two full spraying seasons of regular use.

Battery Care

Proper battery maintenance is essential for reliable performance. Store batteries at 50–60% charge in a cool, dry place (40–80°F), and perform a charge-discharge cycle every three months. Key tips include:

- Use only chargers recommended by the manufacturer.

- Clean battery terminals regularly to ensure good connections.

- Inspect batteries for swelling or damage before each use.

- Balance charge cells periodically to extend battery life.

Propeller and Motor Inspection

Once the batteries and spraying components are in order, shift your attention to the motors and propellers to ensure the entire system runs smoothly. For drones covering over 667 hectares, inspect motor screws and shafts monthly for any signs of deformation or looseness.

Daily motor care includes:

- Manually rotating motors to check for smooth operation.

- Cleaning them with a mild soap solution after exposure to chemicals.

- Ensuring mounting points are securely attached.

- Checking the condition of propeller clip gaskets.

Keep a log of motor hours, cleaning dates, and any unusual sounds to track performance and address potential issues early.

Rust Prevention

Taking care of your drone involves more than just daily cleaning and regular maintenance - it’s also about protecting its metal parts from rust. Rust prevention plays a key role in keeping your drone in top shape and extending its lifespan.

Rust Protection Methods

One of the best ways to keep rust at bay is by implementing a solid protection routine. After cleaning your drone, make sure to dry every part carefully, paying extra attention to joints and connection points. Keeping components clean and dry helps ensure that lubricants work as they should.

Here’s a quick guide to protecting specific parts:

| Component | Protection Method |

|---|---|

| Frame | Waterproof superhydrophobic spray |

| Metal joints | Anti-corrosion spray |

| Battery contacts | Contact cleaner |

| Exposed screws | Rust-resistant coating |

Start by applying a waterproof superhydrophobic spray to key areas. This creates a moisture-repelling shield without interfering with the drone’s aerodynamics. Afterward, focus on lubricating essential parts to prevent rust buildup.

Parts Lubrication

Lubrication is crucial for preventing rust and ensuring that moving parts like bearings and hinges operate smoothly. To get the best results, follow these tips:

- Apply grease when parts are warm to help it penetrate better.

- Lubricate all moving parts thoroughly before putting the drone in seasonal storage.

- Use farm-grade lubricants designed specifically for agricultural equipment.

Stick to a regular lubrication schedule based on how often you use your drone. Before applying fresh grease, clean off any old residue from fittings. For ball or roller bearings, remember to grease them while the drone is stationary. If storing the drone for a season, add a light coating of lubricant and occasionally rotate components to prevent oil from separating. These steps will help keep everything running smoothly and rust-free.

sbb-itb-3b7eef7

Off-Season Storage

Taking care of your agricultural drone sprayer during its downtime is just as important as maintaining it during the active season. Proper storage not only ensures your drone is ready to go when you need it but also helps avoid unnecessary repairs and prolongs its lifespan. Think of it as an extension of your regular cleaning and maintenance routine - only this time, it's about safeguarding your equipment when it's not in use.

Battery Storage

Batteries are the lifeblood of your drone, and how you store them during inactive periods can make a big difference. Here's a quick guide to keeping them in good shape:

| Storage Duration | Recommended Charge Level | Required Actions |

|---|---|---|

| 5-10 days | 50-70% | Regular monitoring |

| Over 10 days | 40-60% | Check every 2-3 months |

| Seasonal storage | 40-60% | Perform a full charge/discharge cycle quarterly |

For longer storage periods, remove the batteries from the drone and place them in a fireproof container. As Danny Fobian puts it:

"Drone batteries are a substantial investment for any pilot. They're not something you can throw in the shop and dig out next season when you're ready to start flying again."

Winter Storage

Once you've completed your regular maintenance, prepping your drone for winter storage is the next step. Start by removing all nozzle components - caps, tips, and gaskets - and cleaning them thoroughly. Store these parts separately to prevent seals from degrading over time.

For those storing their drone in non-climate-controlled spaces, these steps are essential:

- Spray System Protection: Flush the spray lines with clean water until they're clear. In areas where freezing temperatures are common, pump RV antifreeze through the system to avoid damage from ice buildup.

- Component Care: Keep the remote controller indoors and store the drone in a dry, elevated spot to keep it safe from pests and moisture.

Danny Fobian also emphasizes:

"Keeping a drone clean, dry and away from pests is the best way to maximize your investment and ensure you don't have costly repairs waiting when you're ready to start spraying next spring."

While most drones can handle storage temperatures as low as -4°F, a controlled environment offers even better protection. Before storing, wipe down all surfaces with a clean cloth to remove lingering chemical residue or dust. These small steps can make a big difference when it's time to bring your drone back into action.

System Checks and Fixes

Alongside daily cleaning and routine maintenance, performing system checks ensures every component operates as it should. Regular testing and troubleshooting help avoid unexpected downtime during the critical spraying season.

Spray System Setup

Start by confirming the flow meter's accuracy and setting the correct spray patterns. Here's a quick calibration guide:

| Testing Parameter | Target Range | Verification Method |

|---|---|---|

| Wind Speed | 2-10 mph | Weather station or anemometer |

| Swath Overlap | 10-30% | Water-sensitive paper |

| Flow Rate | Equal across nozzles | Timed collection test |

| GPS Accuracy | 2-3 cm (RTK) | Position verification |

"Swath test anytime you set up a new drone. This will allow you to work out the kinks and make sure all equipment is functioning properly."

To verify swath width and distribution, position water-sensitive paper perpendicular to the flight path. This step is crucial for spotting irregularities in coverage. For instance, Jake Masters, Market Manager at Rantizo, once identified streaking in spray patterns caused by chemical blends with crop oil during such a test.

After calibration, inspect all components thoroughly to catch and address potential problems early.

Quick Fixes

When issues arise, quick troubleshooting can get your drone back in the field without major delays. Here are some common problems and their solutions:

Clogged Nozzles

Rinse nozzles daily with water or an appropriate solvent. If clogging continues, double-check mixture ratios and filtration systems.

Battery Performance

Regularly inspect batteries for corrosion in charging ports and test their ability to hold a charge. Clean battery contacts daily with 95% alcohol to ensure reliable connections.

Motor Issues

Manually rotate propellers and listen for unusual sounds, such as bearing wear or motor strain. Addressing these signs early can prevent mid-flight failures.

"Calibrate your pumps before doing any testing. This makes sure your drone is functioning properly and that your overall coverage isn't negatively impacted."

- Ethan Noll, Western Corn Belt Hub Lead

Summary

Taking care of your drone isn't just about keeping it running - it's about extending its lifespan and avoiding expensive downtime. Here's a recap of the key maintenance practices that help protect your investment and keep your drone performing at its best.

Daily cleaning and inspections are the backbone of drone maintenance. Regular attention prevents chemical buildup and shields critical components from unnecessary wear and tear.

Battery care plays a huge role in ensuring your drone operates smoothly over the long haul. Storing batteries at 50% charge in a controlled environment and keeping an eye on their health can make a big difference in their performance and reliability.

Here’s a quick reference table to highlight the main maintenance areas and how they impact your drone’s performance:

| Maintenance Focus | Impact on Performance | Recommended Frequency |

|---|---|---|

| Spray System | Consistent application rates | Daily cleaning, weekly check |

| Frame & Motors | Flight stability and safety | Pre- and post-flight checks |

| Software Updates | Optimal operation | Monthly |

| Sensor Calibration | Accurate data collection | Bi-weekly |

Preparing your drone for winter storage is another critical step to ensure it’s ready for action when the season changes. Andrea Ciotti from Aerial Ag Solutions emphasizes this point:

"Regular maintenance, care, and safe flying practices are essential for the longevity and safe operation of your aerial agriculture drone."

With the crop-spraying drone market projected to hit $3.41 billion by 2025, protecting your equipment through proper care is not just smart - it’s essential for staying ahead in the game.

FAQs

How often should I maintain my agricultural drone sprayer to keep it in top condition?

To keep your agricultural drone sprayer running smoothly, make sure to carry out regular maintenance every 2-3 months and plan for a thorough inspection at least once a year. When the drone is in frequent use, daily cleaning is a must to avoid buildup and reduce wear and tear.

Key maintenance tasks include inspecting and replacing parts such as nozzles and pumps, checking wiring and connections, and ensuring the system is calibrated correctly. Storing the drone in a clean, dry environment when it's not in use is another simple but effective way to prolong its lifespan and ensure it continues performing at its best.

How should I store agricultural drone batteries during the off-season to keep them in good condition?

To keep your drone batteries in good shape during the off-season, make sure they’re stored with a charge level between 40-60%. Find a cool, dry spot with a temperature of 60°F to 70°F - far from heat, cold, or humidity. It’s also a good idea to check the charge every 2-3 months and top them off to the recommended level if needed. Always remove the batteries from the drone before storing them to prevent unnecessary wear or damage. Following these tips will help prolong the life of your batteries and ensure they’re ready to go when the season kicks off.

How can I protect my drone's metal parts from rust and corrosion in humid conditions?

To keep your drone’s metal parts in good shape, especially in humid conditions, it’s important to take a few precautions. Start by using a corrosion inhibitor. This creates a protective layer that helps keep moisture from causing rust. Another key step is to clean your drone often. Dirt and debris can hold onto moisture, which increases the chance of corrosion. After cleaning, make sure every part is completely dry before using or storing the drone.

When it comes to storage, place your drone in a cool, dry space. Adding desiccants, like silica gel packs, can help absorb any extra moisture. Try to avoid exposing your drone to rain or areas with high humidity for long periods. For extra protection, you might want to consider electroplating or applying protective coatings to the metal parts. By sticking to these practices, you can help your drone’s metal components last longer.