Call or Text: +1 (208) 425-2990

Email: Sales@DroneSprayPro.com

Drone Emergency Landings vs. Manual Recovery

Share

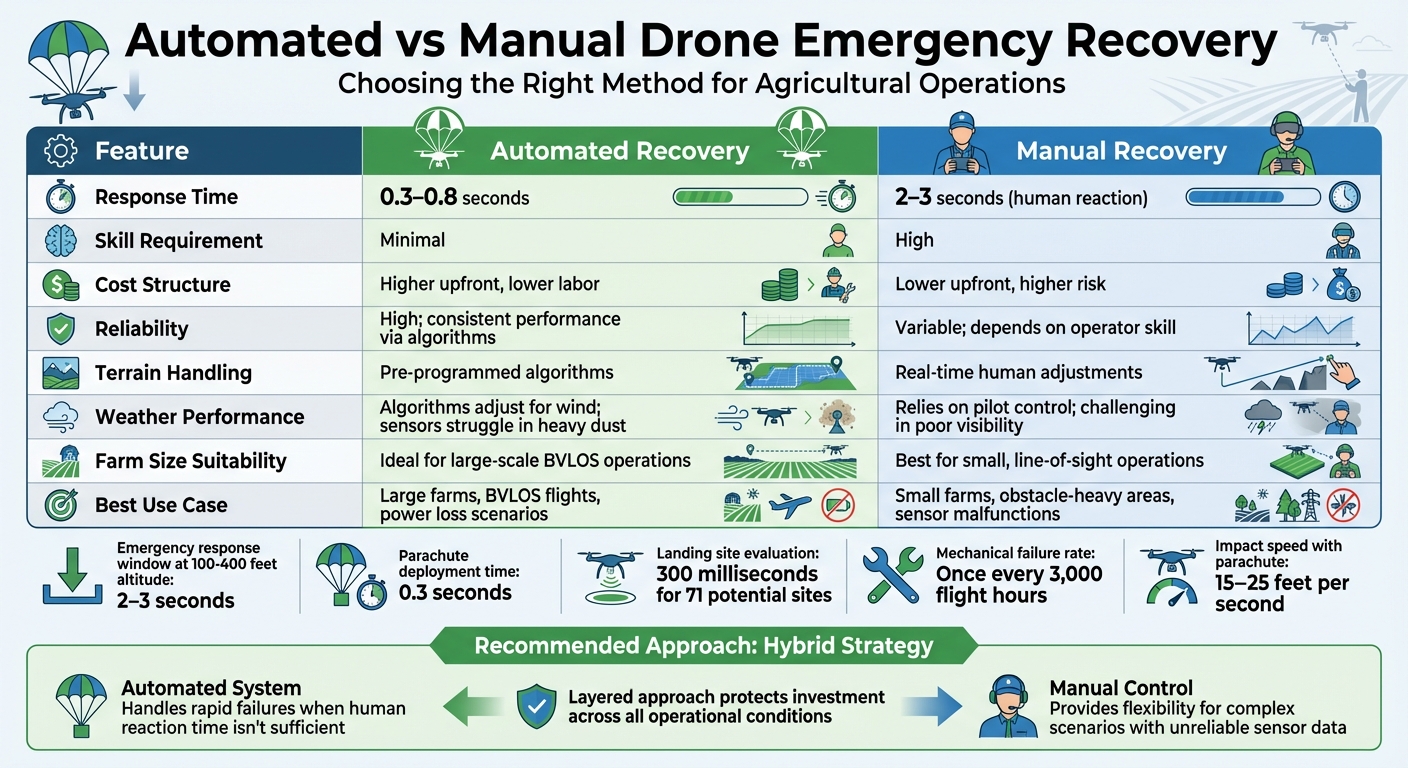

When agricultural drones fail mid-flight, the choice between automated emergency landings and manual recovery can make or break operations. Each method has strengths and weaknesses depending on the situation, terrain, and operator skill. Here's what you need to know:

- Automated systems use sensors, GPS, and protocols to respond in under a second, ensuring consistent performance and reducing human error. They're ideal for high-stakes scenarios like power loss or BVLOS (Beyond Visual Line of Sight) flights.

- Manual recovery relies on operator expertise to handle unpredictable issues like signal interference or sensor errors, offering flexibility and precision in complex environments.

Quick Comparison:

| Feature | Automated Recovery | Manual Recovery |

|---|---|---|

| Response Time | 0.3–0.8 seconds | Human reaction (~2–3 seconds) |

| Skill Requirement | Minimal | High |

| Cost | Higher upfront, lower labor | Lower upfront, higher risk |

| Terrain Handling | Pre-programmed algorithms | Real-time human adjustments |

| Best Use Case | Large farms, BVLOS flights | Small farms, obstacle-heavy areas |

Automated systems excel in speed and consistency, while manual methods shine in adaptability for unique challenges. For most operations, a hybrid approach combining both methods can ensure safer and more efficient outcomes.

Automated vs Manual Drone Recovery: Speed, Cost, and Performance Comparison

I Almost Lost My Drone, Emergency Landing Procedures

sbb-itb-3b7eef7

How Automated Emergency Landing Systems Work

Automated emergency landing systems rely on a combination of sensor networks and advanced software protocols - primarily GPS and GNSS - to keep track of a drone's position in relation to a designated safe zone. When a failsafe event occurs, such as low battery, signal interruption, or equipment failure, the system kicks into action, initiating a return sequence.

An Inertial Measurement Unit (IMU) plays a key role in maintaining stability by monitoring the drone's pitch, roll, and yaw in real time, feeding this data to the flight controller. For spray drones, this is particularly important because shifting payload weights or sudden wind gusts can throw off balance, requiring constant adjustments.

Real-Time Kinematic (RTK) positioning takes accuracy to the next level by correcting GPS drift. Using data from a ground-based station, RTK ensures the drone lands with centimeter-level precision. This is critical for tasks like landing between crop rows, on tight docking pads, or away from sensitive equipment. As stated in ArduPilot documentation:

The ideal setup for good automatic landing is to have a Lidar. A Lidar can measure the distance to the ground very accurately, and doesn't suffer from drift... Alternatively, you can use a high precision GPS as the altitude source instead of the barometer [6].

These positioning technologies form the backbone of the advanced obstacle avoidance and failsafe features discussed below.

Core Technologies in Automated Emergency Landings

Obstacle avoidance sensors, such as LiDAR and computer vision, are constantly at work scanning the terrain. They assess factors like slope, surface roughness, and nearby obstacles to identify safe landing zones. For example, in 2025, researchers Huseyin E. Tekaslan and Ella Atkins developed a contingency landing planner that analyzed 71 potential road landing sites in just 300 milliseconds on a standard laptop. This system successfully guided a Cessna 182 with thrust failure to a safe landing in Long Island, New York [1]. These same principles are directly applicable to agricultural drones.

In addition to positioning and obstacle detection, fail-safe mechanisms like parachutes offer another layer of protection. These parachutes can deploy in as little as 0.3 seconds, reducing impact speeds to 15–25 feet per second - well within the military's crash landing limit of 26 feet per second (MIL-STD-1290A) [2]. Before deployment, the system shuts off the motors to prevent the canopy from tangling in the rotors. Backup batteries and burn wire systems ensure the parachute deploys even if the main power source fails.

Ground Control Station (GCS) failsafes add another safety net by monitoring the communication link between the drone and its operator. If no MAVLink heartbeat - a signal confirming active communication - is detected within five seconds, the system initiates an automatic response. This could include a "Return to Launch" (RTL) command or an immediate landing [5]. This feature is especially useful in remote agricultural areas, where signal interference might otherwise lead to unnecessary failsafe actions.

Advantages of Automated Emergency Landings

These systems bring several key benefits to the table. One major advantage is their consistency - they perform reliably regardless of the operator's skill level or mental state. Once programmed, the system follows a precise glide path, taking into account factors like wind, payload weight, and terrain. This repeatability is particularly useful in large-scale farming operations where one operator might oversee multiple drones.

Another benefit is reduced operator stress. When a critical issue arises, such as a low battery warning or signal loss, the system takes over immediately. This eliminates the need for the operator to quickly assess the situation and manually guide the drone to safety. As Mohsen Farajijalal et al. explain [2]:

The ability to execute controlled and predictable emergency landings can significantly mitigate the risks associated with UAV operations, paving the way for their wider integration into airspace and everyday life.

For Beyond Visual Line of Sight (BVLOS) operations, automation is a game-changer. Without direct visual contact, manual recovery is nearly impossible. Automated systems, equipped with onboard sensors, can navigate back to a predetermined safe location - an increasingly critical capability as agricultural spray operations expand to cover thousands of acres with platforms like the ABZ L30 Agricultural Drone.

How Manual Recovery Methods Work

Manual recovery puts control directly in the hands of operators when automated systems fall short during emergencies. Instead of relying on pre-programmed responses, pilots use real-time judgment, aided by tools like radio transmitters and ground control station (GCS) software, to safely navigate the aircraft.

While automated systems are dependable for routine tasks, manual recovery becomes essential in handling unexpected situations. Operators rely on telemetry data - such as battery voltage, GPS strength, vibrations, and EKF (Extended Kalman Filter) performance - displayed on GCS applications like Mission Planner or APM Planner 2. For instance, during a failsafe event like signal loss or a low battery, pilots can regain control by toggling the flight mode switch on their radio controller. The ArduPilot documentation explains:

If the pilot wished to re-take control in Loiter he/she would need to change the flight mode switch to another position and then back to Loiter. This can be done via the re-connected GCS also [5].

Once control is re-established, the operator uses joysticks to adjust throttle, pitch, roll, and yaw. This hands-on control allows the pilot to navigate around obstacles like power lines, irrigation systems, and uneven terrain, while also compensating for payload shifts or strong winds [2]. These maneuvers form the basis of specialized recovery flight modes designed for specific conditions.

Operator-Controlled Recovery Techniques

The choice of flight mode plays a crucial role in manual recovery. For example, Position mode helps hold the drone at a specific GPS coordinate when the signal is reliable. However, if GPS fails and triggers a "Global Positioning Signal Invalid" warning, the operator should switch to Altitude or Atti mode, which rely on barometric and inertial data [7] [8].

In Altitude mode, the drone maintains a stable height but does not hold its horizontal position. This requires the operator to manually counteract wind drift. For drones carrying heavy payloads, manual modes can make the aircraft more responsive to inputs, resulting in quicker movements compared to automated modes [8]. To ensure a safe landing, operators often depend on real-time camera feeds to visually scan the ground for obstacles and suitable landing spots. If the GCS tablet malfunctions but the radio link remains active, the pilot can switch to manual control using the physical remote controller, enabling swift action to avoid crashes.

Advantages of Manual Recovery

Manual recovery offers several key benefits, especially in unpredictable agricultural settings. Its primary strength lies in flexibility - pilots can instantly adapt to sudden obstacles or irregular terrain that automated systems might misinterpret.

Another advantage is precision. For example, when landing between narrow crop rows or on a small docking pad, manual joystick inputs allow the pilot to position the drone exactly as needed. Operators can also monitor system health indicators, such as excessive vibrations or EKF issues, and adjust their approach accordingly.

Additionally, manual recovery lets pilots bypass certain automated safety features when necessary. For instance, obstacle avoidance systems might prevent landing in specific scenarios. By switching to manual control, the operator can override these restrictions to guide the drone safely to the ground [8]. This ability to take full control can mean the difference between a smooth landing and a forced crash in an unsuitable area.

Pros and Cons Comparison

Choosing between automated emergency landing systems and manual recovery methods involves weighing the trade-offs in key performance areas. Factors like response time, operator skill requirements, and cost play a major role in determining which approach suits your needs.

Automated systems shine when it comes to speed and consistency. They can deploy parachutes in as little as 0.3 seconds and evaluate multiple landing sites in just 300 milliseconds using onboard processing [1]. This rapid response is critical since most spray drones operate at altitudes of 100–400 feet, where the emergency response window is typically only 2–3 seconds [1]. Manual recovery methods, by comparison, often can't meet this narrow time frame.

"When systems fail at typical operating altitudes of 100–400 feet, the window for emergency response can be as brief as 2–3 seconds, requiring rapid and reliable recovery mechanisms." - Authoritative Source, Xray/GreyB [1]

However, automated systems come with higher upfront costs due to the need for advanced sensors, redundant hardware, and fail-safe mechanisms. Manual recovery, while cheaper initially, presents a higher risk of equipment loss and requires skilled operators, who often command higher wages [9]. For larger operations with multiple drones, automation can reduce labor costs significantly. On the other hand, smaller farms with only a few drones operating within visual range may find manual methods more practical. The table below breaks down the key differences in reliability, cost, and usability between the two options.

| Category | Automated Emergency Landing | Manual Recovery Methods |

|---|---|---|

| Reliability | High; consistent performance via algorithms [3][1] | Variable; depends on operator skill and signal stability [2] |

| Response Time | Sub-second (0.3–0.8 seconds) [1] | Slower; human reaction often exceeds 2–3 seconds [1] |

| Operator Skill | Minimal to none required [2] | High; requires trained and experienced pilots [2] |

| Cost Structure | High upfront cost; lower long-term expenses [9] | Low initial cost; higher risk and labor costs [9] |

| Weather Performance | Algorithms adjust for wind; sensors struggle in heavy dust [1] | Relies on pilot control; challenging in poor visibility [2] |

| Farm Size Suitability | Ideal for large-scale BVLOS operations [3] | Best for small, line-of-sight operations [2] |

Another important consideration is weather. Automated systems use advanced algorithms to adjust for wind and maintain stability, even when visibility is reduced. However, extreme conditions like heavy dust or fog can interfere with sensors [1]. Manual recovery, by contrast, depends entirely on the pilot's ability to visually track and control the drone, which becomes increasingly difficult in adverse weather. This makes automation particularly valuable for Beyond Visual Line of Sight (BVLOS) operations, which are becoming more common on larger farms [3]. Balancing these trade-offs is crucial for ensuring safety and protecting equipment in crop spraying scenarios.

Applications and Safety Outcomes in Crop Spraying

Crop spraying operations adapt recovery strategies based on field size, terrain, and the type of drone being used. For large farms, fixed-wing drones are ideal, as they efficiently cover vast areas with automated recovery systems. On the other hand, multirotor drones like the DJI Agras T25 excel in smaller fields with obstacles, offering precise manual control for tricky environments [2] [4].

To enhance safety during spraying, agricultural drones are equipped with cutting-edge technologies that support both automated and manual operations. For instance, Drone Spray Pro's fleet, including the DJI Agras T50, features phased array digital radar and binocular vision to detect obstacles from all angles. These systems automatically navigate around hazards during routine flights. Additionally, RTK positioning ensures centimeter-level accuracy, even during emergency Return-to-Home maneuvers [10] [11] [12]. Other models, such as the Talos T60X and XAG, also offer robust obstacle avoidance, giving operators peace of mind whether using automated routes or manual controls.

For large-scale spraying tasks, automation significantly boosts safety and efficiency. The DJI Agras T40, for example, can adjust its trajectory automatically to avoid crashes, confining any potential incidents to designated no-crash zones. Impressively, it can cover up to 40 acres per hour, making it a powerful tool for expansive operations [1] [11].

Meanwhile, manual recovery proves invaluable in fields with complex layouts or numerous obstacles. In such scenarios, the DJI Agras T25 stands out. Its FPV gimbal camera provides real-time visual feedback, while its compact, foldable design - 21% smaller than previous models - makes it perfect for tight landings. Features like reverse directional spraying and the DJI Relay system ensure uninterrupted control, even in areas with signal interference [4]. To support operators, Drone Spray Pro offers comprehensive bundles that include RTK dongles, extra batteries, and chargers, catering to operations ranging from a 10-acre orchard to a sprawling 500-acre wheat field [4].

How to Choose Between Methods

The recovery method you choose should align with your drone’s weight and the applicable regulatory requirements. For example, agricultural spray drones under 55 lbs fall under FAA Part 107 regulations. Heavier models, however, require Section 44807 exemptions and Part 137 certification for applying pesticides [13][14]. These distinctions affect not only the required safety equipment but also the training operators must complete. In Idaho, Drone Spray Pro provides expert guidance to help farmers navigate these licensing hurdles and choose the right model - whether it’s a DJI Agras, Talos, or XAG drone - for their specific needs. Making the right decision here is critical to ensuring safe and compliant operations.

Operational dynamics also play a major role in selecting a recovery method. Failures at typical spraying altitudes leave little room for error, so rapid response systems are key [1]. Automated recovery tools, such as parachutes, can deploy in as little as 0.3 seconds, addressing catastrophic issues like total power loss [1]. On the other hand, manual recovery methods work better for problems like sensor malfunctions or signal interference. In these cases, operators can use FPV cameras to guide the drone to safety. The choice of recovery system should reflect the most frequent types of failures encountered in your operations.

Terrain and field layout are additional factors to consider. For instance, Idaho orchards often feature narrow rows and uneven slopes, making drones with spherical radar and RTK positioning - like those included in Drone Spray Pro’s packages - ideal. These drones combine automated obstacle avoidance with manual override options, giving operators flexibility. In contrast, large, open fields allow automated systems to manage routine tasks efficiently, though operators should still maintain manual control skills for unexpected challenges.

By combining these considerations, you can develop a more effective safety strategy. A hybrid approach that leverages both automated and manual recovery systems offers a balanced solution.

"Integrating multiple approaches based on the UAV type and mission requirements can achieve broader cover of emergency situations compared to using a single system for a specific scenario." - Mohsen Farajijalal, Department of Mechanical Engineering, University of California [2]

Drone Spray Pro supports this strategy with bundled packages that include RTK dongles, extra batteries, and chargers. Automated systems handle rapid failures when human reaction time isn’t enough, while trained operators can step in for more complex scenarios where sensor data may be unreliable. This layered approach helps protect your investment, whether you’re managing a small orchard or overseeing large-scale operations.

Conclusion

Choosing the right recovery approach depends on your specific operational needs and timing requirements. Automated systems are ideal for handling critical failures within a 2–3 second window at altitudes of 100–400 feet [1]. On the other hand, manual recovery provides the flexibility needed for situations that aren't as time-sensitive.

This decision is especially important given the risks associated with agricultural drone operations. Mechanical failures are estimated to occur once every 3,000 flight hours [1], making a reliable recovery plan essential to safeguard your investment and maintain safe operations. For agricultural spray drones navigating Idaho's varied terrain - ranging from flat fields to sloped orchards - a combination of both methods often works best. Automated systems can manage sudden power losses, while manual overrides allow operators to address navigation errors or interrupt automated sequences when they maintain clear visual control.

The specifications of your drone and the environment in which it operates should guide your recovery strategy. Heavier drones may require different safety measures than lighter ones, and FAA regulations often vary based on weight class. Terrain complexity is another major consideration; drones operating over uneven ground or areas with obstacles benefit from advanced features like LIDAR or vision-based sensors for real-time landing site assessments - something manual recovery cannot typically provide [3]. These technical factors play a crucial role in ensuring safe and effective operations across diverse field conditions.

To make the most of both recovery methods, explore packages from Drone Spray Pro. These bundles are designed to meet the technical and operational needs of modern agricultural spraying. Whether you're using a DJI Agras, Talos T60X, or XAG model, these packages include essentials like RTK positioning, extra batteries, and accessories that support both automated and manual recovery systems. This layered setup ensures you’re prepared to safely retrieve your drone, no matter what challenges arise in the field.

FAQs

What are the advantages of using automated emergency landing systems for agricultural drones?

Automated emergency landing systems bring several advantages to agricultural drones. These systems are designed to identify critical problems - like losing control or a GPS signal - and guide the drone to a safe landing spot without needing human input. This helps prevent crashes, safeguards nearby property, and ensures the drone can be retrieved intact.

These systems can autonomously adjust the drone's altitude and land it in pre-defined safe zones or even return it to the original launch point. This feature is particularly helpful in agricultural settings, where recovering a drone manually can be tricky or even dangerous. Plus, by reducing downtime and minimizing potential damage, these systems provide a dependable solution for operators looking to maintain efficiency and safety.

How are unexpected situations managed using manual recovery methods during drone flights?

Manual recovery methods put the responsibility on the pilot to quickly assess and manage unexpected situations during drone flights. This can involve actions like keeping the drone within visual line of sight, using return-to-home or hover features, or executing an immediate landing if communication or control is lost.

These approaches demand that the operator remains vigilant and ready to act in emergencies, prioritizing the safety of both the drone and its surroundings. While they can be effective, manual recovery heavily relies on the pilot’s skill and reaction speed, which may not always match the accuracy and efficiency of automated systems.

What should you consider when deciding between automated emergency landing systems and manual drone recovery?

When choosing between automated emergency landing systems and manual drone recovery, it’s essential to consider the specific demands of your operation and the environment where your agricultural drone operates.

Automated systems are equipped with advanced features like obstacle detection and autonomous navigation. These technologies allow drones to quickly identify safe landing spots during emergencies. They excel in reducing pilot workload and responding swiftly to issues like lost communication or hazardous conditions. If your priority is safety and efficiency in critical, time-sensitive scenarios, automation is a strong choice.

On the flip side, manual recovery depends on human control and judgment. This approach shines in complex or unpredictable situations where automation might struggle. Operators can make informed, situation-specific decisions, but manual recovery can be slower and more error-prone, especially under pressure.

For optimal results, think about combining both methods in your safety protocols. Automated systems bring speed and reliability, while manual recovery offers the flexibility to handle unique challenges when precision is key.