Best Practices for Tank Mixing in Drone Spraying

Share

Tank mixing for drone spraying requires precision. Poorly mixed chemicals can clog nozzles, damage crops, and disrupt operations. Here's how to get it right:

- Chemical Compatibility: Check labels or conduct a jar test to avoid clumping or separation. Pay attention to pH and formulations (e.g., powders vs. liquids).

- Mixing Order: Start with clean water, add dry formulations first, then liquids, and finish with adjuvants or surfactants.

- Additives: Use agents like Drift Reduction (DRAs) for better control and Ammonium Sulfate (AMS) for hard water conditioning.

- Coverage Testing: Use water-sensitive paper or dyes to ensure even spray distribution.

- Safety: Wear PPE, mix in ventilated areas, and keep chemicals away from water sources.

- Compliance: Follow FAA rules, EPA guidelines, and state laws. Keep detailed records and ensure certifications are up to date.

Key takeaway: Proper mixing ensures effective application, minimizes waste, and avoids costly errors. Follow these steps to make the most of your drone spraying operations.

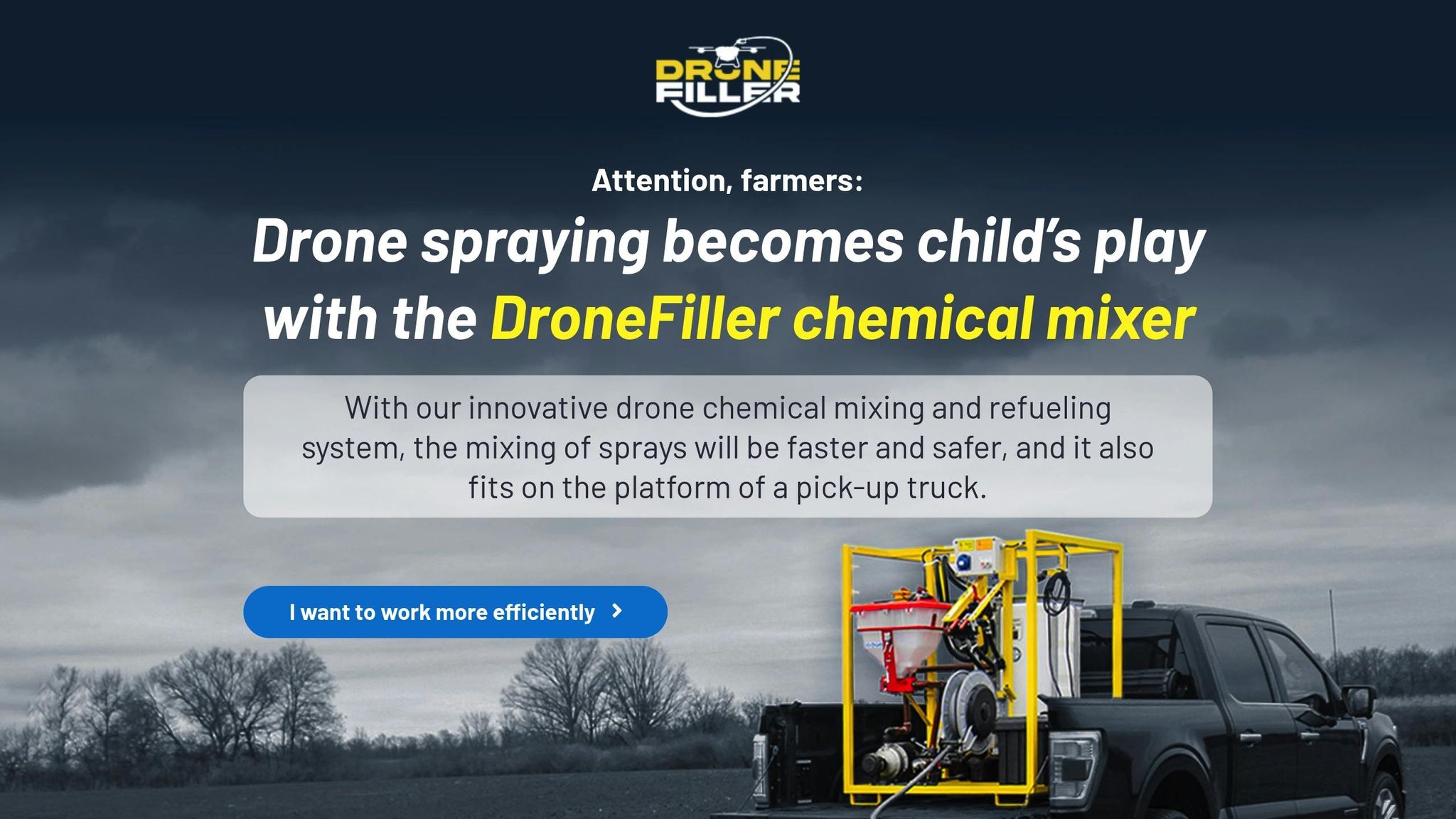

DroneFiller: Effortless Chemical Mixing for Your Agri Drones!

Chemical Compatibility and Mixing Order

Mixing incompatible chemicals can lead to clumping, separation, or a drop in effectiveness. This is especially critical for drones, where limited tank space and minimal agitation demand precise handling.

How to Check Chemical Compatibility

Start by examining the product labels - they’re packed with essential details about which chemicals can be safely mixed. Many herbicides, fungicides, and insecticides include specific compatibility guidelines or warnings. If the label doesn’t provide enough clarity or you’re working with a complex mix, conduct a jar test. To do this, combine small amounts of each chemical in a clear container, using the same ratios planned for your drone tank. Let the mixture sit briefly, then check for any signs of clumping, separation, or color changes.

Pay attention to pH levels too. For instance, many fungicides thrive in slightly acidic conditions, while certain herbicides perform better in a neutral to slightly alkaline range. A simple pH test strip can help ensure your water and chemicals are within the ideal range.

Also, keep in mind the type of formulation. Dry products like wettable powders or water-dispersible granules can be trickier to work with compared to liquid options like emulsifiable concentrates or suspension concentrates.

Once compatibility is confirmed, follow the correct mixing sequence to ensure everything stays stable.

Proper Mixing Order Steps

After verifying compatibility, the right mixing order becomes critical for maintaining a stable solution.

- Begin with clean, lukewarm water to help dissolve the chemicals effectively.

- Add dry formulations first, but pre-mix them into a slurry to avoid clumping.

- Gradually introduce liquid concentrates into the agitated mixture, allowing each one to blend fully before adding the next.

- Finally, mix in any adjuvants or surfactants, which are designed to fine-tune the spray mixture.

For drones, where time is tight, a stable mixture ensures smooth and efficient application.

How to Avoid Common Mixing Problems

Certain issues, like precipitation, can arise when dissolved chemicals form solid particles. Hard water, with high levels of calcium or magnesium, often contributes to this. To address this, try a water conditioning agent or switch to a softer water source.

Temperature differences can also cause separation or reduce solubility. Keep all components at similar temperatures to minimize these issues.

Tank cleanliness is another critical factor. Residue from previous applications can react with new chemicals, especially if you’re switching between different types of products. Always clean the tank thoroughly between loads to avoid cross-contamination.

Drone tanks rely on aircraft movement for agitation, which means settling can happen if the mixture isn’t stable enough. Use formulations that remain suspended and mix only what you can apply promptly. Anti-settling agents can help keep the mixture evenly distributed.

Foaming is another common problem. It can interfere with accurate tank level readings and even cause pump issues. If foaming becomes excessive, opt for an agricultural-grade defoaming agent rather than a household product to resolve the issue effectively.

Using Additives for Drone Applications

Additives play a key role in maintaining uniform mixtures during drone spraying. Unlike traditional ground rigs that rely on mechanical agitation, drones depend on their motion in flight to keep mixtures consistent. Choosing the right additives ensures your spray solution stays effective throughout the application process, complementing the mixing protocols discussed earlier.

Main Additives for Drone Spraying

- Drift Reduction Agents (DRAs): These additives increase droplet size, reducing the number of fine particles that might drift away from the target area. By thickening the spray solution, they create larger, more consistent droplets that are easier to control and deposit accurately.

- Methylated Seed Oil (MSO): MSO enhances penetration and spreading, particularly on waxy leaf surfaces. This is especially useful when working with lower water volumes per acre. Always follow the manufacturer's recommended application rates for the best results.

- Ammonium Sulfate (AMS): AMS conditions hard water, which can interfere with herbicide performance, and it improves the absorption of certain systemic herbicides. Be sure to consult product guidelines to determine the proper amount for your spray solution.

- Crop Oil Concentrates (COCs): These petroleum-based adjuvants help with penetration and spreading, much like MSO. However, they can be more aggressive, so use caution when applying them to sensitive crops or under conditions that could increase the risk of crop damage.

- Non-Ionic Surfactants: By lowering surface tension, these additives ensure spray droplets spread evenly across leaf surfaces instead of forming beads. This improved coverage is particularly valuable for the concentrated solutions often used in drone spraying.

Selecting Additives Based on Conditions

Environmental factors and crop needs should guide your choice of additives. For instance, if you're spraying in breezy conditions, drift reduction agents can help keep the spray on target, even if it slightly reduces overall coverage.

Temperature and humidity also play a role. In hot, dry conditions, oil-based adjuvants may increase the risk of leaf damage, making silicone-based surfactants a safer choice. On the other hand, in cooler or more humid conditions, penetrating agents can improve chemical uptake more effectively.

Your crop's type and maturity are equally important. Young, tender plants often require gentler additives, while mature crops with waxy leaves may benefit from stronger formulations. Tailor your additive selection to suit both the crop and its growth stage.

Compatibility between additives and active ingredients is another critical factor. For example, some herbicides perform better with water conditioners like AMS when hard water is an issue, while others may need surfactants to optimize coverage. Carefully analyzing your tank mix can help prevent undesirable interactions.

Testing your water quality can also inform your additive choices. Hard water may call for conditioners, while softer water might only need a basic surfactant to improve coverage.

How to Use Additives Correctly

Follow the manufacturer's dosing instructions carefully and add additives only after pesticides have fully dissolved. Always test your mixture on a small area before applying it widely.

Check your spray patterns and adjust nozzle settings as necessary. Conducting small-scale tests helps fine-tune your approach for better results.

Mix only the amount of solution you plan to use immediately, and store products as directed. Keeping detailed records of your additive combinations, along with environmental conditions and application outcomes, can help you refine your methods over time.

Finally, use caution when combining multiple additives. While mixing several products might seem like a good idea, it can lead to compatibility issues or unexpected side effects. As a general rule, stick to one primary adjuvant per application unless you've thoroughly tested and confirmed the effectiveness of your combination.

sbb-itb-3b7eef7

Testing Spray Coverage and Results

Testing your spray coverage is key to ensuring your tank mix is applied effectively and evenly across your field. Even if your mix is carefully prepared, without proper testing, it might not perform as expected. These tests help you spot coverage gaps, fine-tune your spray settings, and confirm your drone application is working as planned - all before scaling up to a full application.

Using Dye to Test Coverage

Water-sensitive paper is a simple yet effective tool for checking spray patterns before treating an entire field. These special cards change color when hit by spray droplets, giving you a clear visual of your coverage. By placing the cards at different canopy heights, you can assess how well the spray penetrates through the crop.

Another option is using food-grade dye mixed with water. A small amount of dye, as recommended by the manufacturer, can be added to your spray tank. This colored mixture highlights where the spray lands on plants and soil, making it easier to spot areas with missed coverage, overlaps, or uneven droplet distribution.

For an even more detailed analysis, fluorescent dyes can be used. These dyes glow under UV light, allowing you to closely examine the spray pattern hours after application. Be sure to follow the dye manufacturer’s guidelines for best results.

When performing dye tests, replicate the actual conditions of your planned application. Match the altitude, speed, and spray pressure you’ll use in the field. It’s also important to document flight parameters like ground speed, spray rate, wind speed, and direction to ensure your test results accurately reflect real-world performance.

How to Read Coverage Test Results

After completing your dye tests, interpreting the results is crucial to improving your application. Water-sensitive cards provide insights into droplet size, density, and distribution across your spray area. A well-executed application will show a uniform droplet pattern with no noticeable gaps. If you find uneven coverage or reduced droplet density, it might point to issues like nozzle problems, incorrect flight altitude, or spray pressure that needs adjusting.

Pay attention to droplet size, as it plays a big role in spray effectiveness. Smaller droplets tend to provide better coverage for contact-based products, while larger droplets are less likely to drift in windy conditions. Additionally, slight overlaps between spray swaths are necessary to avoid untreated areas. If overlaps are inconsistent, you may need to tweak your spray settings.

Environmental factors like wind and temperature also influence your results. Strong winds can cause drift, leading to uneven coverage, while high temperatures can speed up droplet evaporation. Monitoring these conditions and adjusting accordingly can help ensure consistent application.

Tools for Checking Application Accuracy

Several tools can help you verify the accuracy of your spray application. For example, attaching white paper tape to stakes throughout the field provides an inexpensive way to check spray deposition. After spraying, the patterns on the tape can reveal areas with insufficient coverage.

More advanced options include digital spray cards paired with smartphone apps and flow meters integrated into your system. These tools offer real-time data on droplet density, size, and application rates, helping you identify blockages or malfunctions quickly. GPS tracking systems are also invaluable for recording flight paths and spray locations, especially in large or oddly shaped fields.

Specialized spray pattern analyzers can evaluate nozzle performance before you even start spraying. These devices measure how evenly the spray is distributed, helping you spot and fix issues early. Regular nozzle testing is a must to prevent gaps in coverage and maintain consistent performance.

Lastly, weather monitoring tools like wind meters and temperature/humidity sensors provide crucial data to help you decide the best spraying conditions. By combining these tools with thorough testing, you can achieve precise, efficient, and reliable applications every time.

Safety and Regulatory Requirements

When using drones to mix and spray chemicals, following safety protocols and meeting regulatory standards is non-negotiable. Agricultural chemicals, especially in their concentrated forms, require careful handling to protect both people and the environment.

Safety Steps During Mixing and Loading

Personal protective equipment (PPE) is your best defense during chemical mixing. Always review the chemical labels and Safety Data Sheets (SDS) beforehand to understand the specific gear required. This often includes chemical-resistant gloves, protective eyewear, respirators, and coveralls.

Did you know that hand exposure accounts for 50–75% of skin contamination during mixing? Wearing the right gloves can cut that risk by 90–99%. Make sure to use gloves recommended on the chemical label.

Set up your mixing station in a well-ventilated outdoor area, far from water sources, homes, and areas where children are present. Most pesticide-related injuries happen during mixing, especially when containers are open. To avoid spills, use dedicated tools, have spill kits on hand, and inspect your equipment daily.

Good hygiene is also critical. Wash your hands before eating, drinking, or smoking, and shower after completing the job. Only prepare the amount of solution you need for immediate use - this reduces waste and prevents chemical degradation.

Environmental Protection Rules

Protecting the environment starts with knowing the sensitive areas near your spray site. Federal and state laws often require buffer zones around water bodies, schools, residential areas, and organic farms. These buffer distances vary depending on the chemical and application method, so always check local rules before starting.

Drift management is especially crucial when using drones. Smaller droplets are more prone to drifting with the wind, so monitor weather conditions closely. Avoid spraying when wind speeds are high or when the wind direction could carry chemicals into unintended areas.

Keep water sources safe by mixing chemicals far from wells, streams, ponds, or other bodies of water. Use anti-siphon devices or maintain air gaps when filling tanks to prevent backflow contamination. Some states also have specific rules about how far mixing areas must be from water sources, so double-check local guidelines.

Record-keeping is another essential step. Document every application, including the chemicals used, application rates, weather conditions, and GPS coordinates of the treated areas. In many states, these records must be kept for several years and made available for inspection.

FAA Licensing and Operating Requirements

In addition to safety and environmental precautions, drone operators must comply with Federal Aviation Administration (FAA) regulations. For agricultural spraying, this means going beyond recreational drone rules.

All commercial drone operators need a Part 107 Remote Pilot Certificate, which requires passing a written test covering airspace regulations, weather, and flight operations. This certification is valid for two years and must be renewed regularly.

For larger-scale operations, compliance with Part 137 may be required. While Part 107 covers most drone activities, it includes a visual line-of-sight rule, meaning the pilot must keep the drone in sight at all times. This can limit how much area you can treat in a single flight.

Airspace restrictions also play a big role. Before flying, check for temporary flight restrictions, controlled airspace, or special use zones using tools like the FAA's B4UFLY app or sectional charts. Pre-flight checks are critical since airspace conditions can change quickly.

To help with these requirements, companies like Drone Spray Pro offer FAA licensing support, training, and ongoing education. By staying compliant with these regulations, you can ensure your drone operations are both safe and efficient, complementing your safety and environmental practices.

Key Points and Final Tips

Getting tank mixing right for drone spraying means paying close attention to every detail. Here's a quick recap of the most important practices, from ensuring chemical compatibility to following safety rules, to help you achieve the best results.

Main Best Practices Summary

- Chemical compatibility is critical. Always test with small batches first and stick to the correct mixing order: water, adjuvants, and then pesticides. This minimizes the risk of unwanted reactions.

- Additives matter. Surfactants help chemicals penetrate better, drift control agents keep the spray on target, and pH adjusters stabilize the mix. Tailor your additive choices to the weather - use drift control agents on breezy days, and defoamers if the tank gets too foamy.

- Coverage testing is a must. Tools like water-sensitive paper or fluorescent dyes give you a clear picture of your spray quality. Use the results to fine-tune your spray settings.

- Safety protocols protect everyone and the environment. Wear proper PPE, create buffer zones near sensitive areas, and keep thorough records of each application. These steps aren't just smart - they're often legally required.

- Regulatory compliance goes beyond mixing. Stay up to date with FAA rules and local regulations, and make sure your certifications are current.

These practices lay the groundwork for effective drone spraying. Now, let’s explore a few additional tips to take your operation to the next level.

Final Tips for Drone Operators

Before you start spraying, check the chemical labels and review the weather. Wind speed, humidity, and temperature can all affect how the chemicals mix and perform. The perfect conditions in the morning might not work at all by the afternoon if the weather shifts.

Keep your mixing area neat and well-stocked. Use dedicated measuring tools, have spill cleanup supplies on hand, and store everything properly to avoid contamination. A dedicated mixing station can save time, reduce waste, and improve safety.

Track everything - mixing ratios, weather conditions, application rates, and results. This information is invaluable when troubleshooting issues or improving future applications. Digital apps can simplify record-keeping and help you stay compliant with regulations.

Stay connected with suppliers and extension agents. They’re great resources for learning about new products, advanced mixing techniques, and local pest trends. Many suppliers also offer technical support if you run into unusual mixing challenges.

Practice your mixing process during the off-season. Building muscle memory in low-pressure situations lets you work faster and more safely when the busy season hits. Training with experienced operators or through programs like Drone Spray Pro can also sharpen your skills.

Tank mixing is part science, part skill. While following best practices gives you a solid start, experience will help you fine-tune your approach and adapt to changing conditions.

FAQs

What mistakes should I avoid when mixing chemicals for agricultural drone spraying?

When preparing chemical mixtures for agricultural drone spraying, avoiding certain missteps is crucial to ensure both safety and effectiveness:

- Incorrect mixing order: Always start by adding water to the tank before introducing any chemicals. This simple step prevents clumping and ensures a more even mix.

- Chemical incompatibility: Double-check that all chemicals you plan to mix are compatible. Incompatible combinations can lead to harmful reactions, damage your equipment, or reduce the effectiveness of your application.

- Improper agitation: Without proper agitation, your mixture might not blend evenly, leading to inconsistent spraying and uneven coverage.

- Poor labeling: Clearly label all equipment and chemical containers. This minimizes the risk of mix-ups or accidental misuse, which could lead to safety hazards or ineffective applications.

By keeping these practices in mind, you can boost the safety and efficiency of your drone spraying tasks. For more detailed advice, experts like Drone Spray Pro offer specialized solutions tailored to the needs of modern farmers.

How do weather conditions like wind and temperature impact drone spraying results?

Weather conditions, like wind and temperature, are key factors when it comes to effective drone spraying. Let’s break it down:

Wind is a major concern because it can lead to spray drift. This means the chemicals might not reach the target area and could even spread to unintended locations, causing contamination. To avoid this, it’s best to steer clear of spraying on windy days. This helps keep the application precise and avoids wasting chemicals.

Temperature also plays a big role. When it’s too hot, droplets can evaporate quickly before they even reach the crops. This not only reduces coverage but also impacts the overall efficiency of the spray. By keeping an eye on the weather and choosing times when the wind is calm and temperatures are moderate, you can achieve better coverage and get the most out of your drone spraying efforts.

What safety measures should I follow to comply with FAA and EPA regulations when using drones for agricultural spraying?

To operate agricultural drones for spraying in the U.S., you’ll need to meet specific FAA and EPA requirements. Start by obtaining a Part 107 Remote Pilot Certificate and a Part 137 certificate, which are mandatory for applying agricultural chemicals. You’ll also need to register your drone and comply with FAA rules on topics like night flights, swarm operations, and airspace restrictions.

On the EPA side, it’s crucial to use only approved pesticides, wear appropriate personal protective equipment (PPE), and follow strict safety protocols when handling chemicals. Don’t forget to stay informed about local regulations and secure liability insurance to ensure your operations are both compliant and safe.